OLED Data:Display (I2C)

OLED Data:Display (I2C)Hardware connectionControl principleSoftware configurationPin definitionSoftware codeControl functionExperimental phenomenon

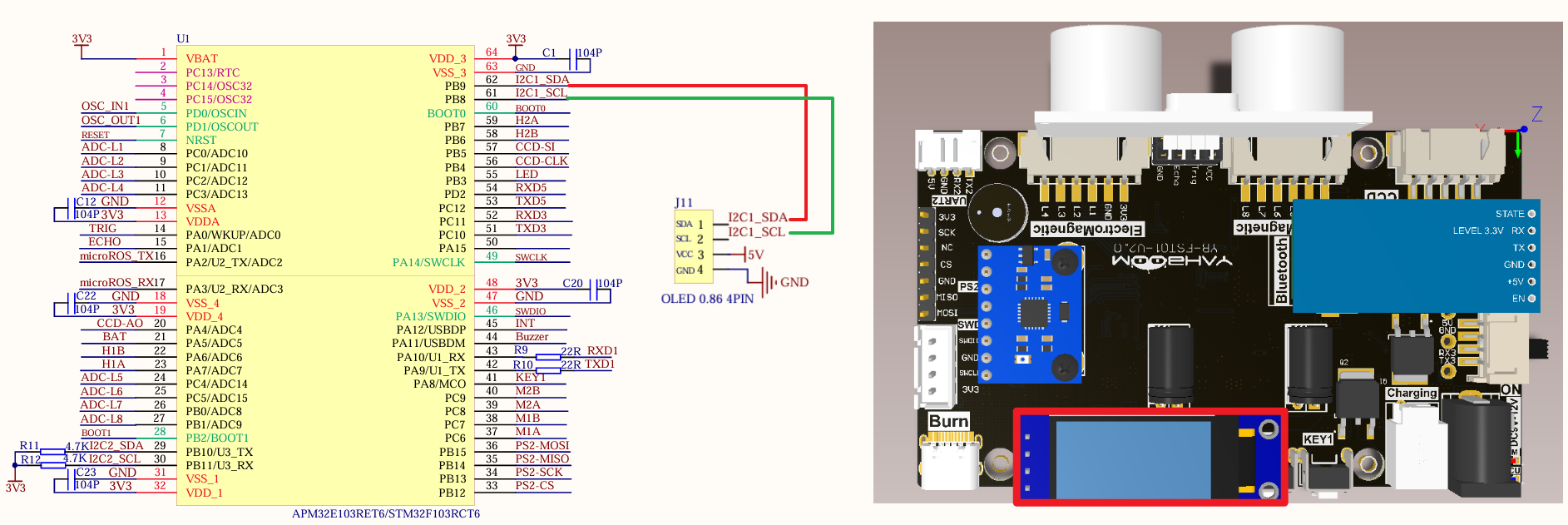

The tutorial demonstrates the use of hardware I2C to drive OLED to display characters.

Hardware connection

Just install it to the corresponding interface:

| Peripherals | Development board | Description |

|---|---|---|

| OLED: VCC | 5V | OLED power supply |

| OLED: GND | GND | OLED common ground |

| OLED: SCL | PB8 | Serial clock line (SCL) |

| OLED: SDA | PB9 | Serial data line (SDA) |

Control principle

Use the I2C1 peripheral interface to communicate with the 0.91-inch OLED display.

OLED

| Product | 0.91 inch OLED display |

|---|---|

| Resolution | 128*32 |

| Control chip | SSD1306 |

| Communication method | I2C (IIC) |

| Working voltage | 3.3~5V (5V recommended) |

| I2C interface | VCC: positive power supply (5V) GND: power ground SCL: I2C bus clock signal SDA: I2C bus data signal |

I2C (Inter-Integrated Circuit) bus is a serial communication protocol consisting of a serial data line (SDA) and a serial clock line (SCL).

Serial data line (SDA): used to transmit data

All devices use the same data line to communicate by transmitting data in binary form.

Serial Clock Line (SCL): Used to synchronize data transfer

xxxxxxxxxxThe clock line generates pulses at a specific frequency to ensure that both the sending and receiving devices can transmit data at the same timing.

Multi-device communication: The I2C interface uses an address-based device identification mechanism to select a specific device to communicate with.

xxxxxxxxxxEach I2C device has a unique address that identifies the device; the master device selects a specific device to communicate with by sending the device address

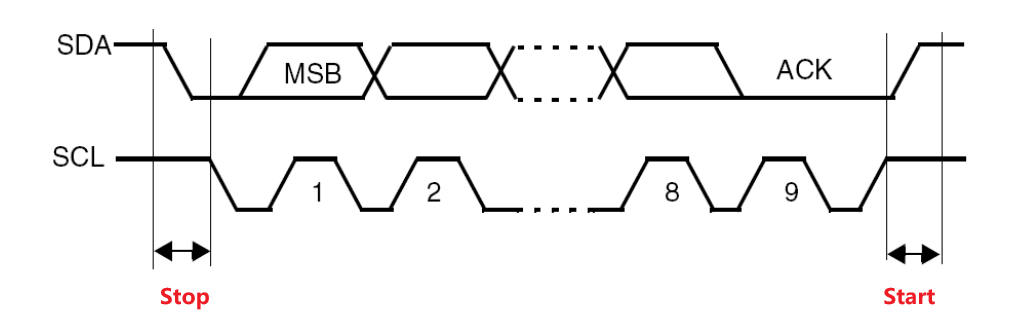

I2C communication

IIC bus timing diagram

Idle state

SCL high level, SDA high level;

Start condition

SCL high level, SDA falling edge;

Stop condition

SCL high level, SDA rising edge;

Data transmission

SCL low level, SDA rising or falling edge;

Response signal

After receiving data from the device, it will send a low level to the master device to indicate successful reception;

Data validity

When the clock line is high, the data line must remain stable; when the clock line is low, the data line is allowed to change.

xxxxxxxxxxSCL: high level → used for the start and end of communicationSCL: low level → used for data transmission and end

Software configuration

Pin definition

| Main control chip | Pin | Main function (after reset) | Default multiplexing function | Redefine function |

|---|---|---|---|---|

| STM32F103RCT6 | PB8 | PB8 | TIM4_CH3 | I2C1_SCL/CAN_RX |

| STM32F103RCT6 | PB9 | PB9 | TIM4_CH4 | I2C1_SDA/CAN_TX |

Software code

Since the default function of the pin is the ordinary IO pin function, we need to use the redefine function.

xxxxxxxxxxProduct supporting materials source code path: Attachment → Source code summary → 2. Extended_Course → 4. OLED

Control function

The tutorial only briefly introduces the code, you can open the project source code to read the details.

OLED_I2C_Init

xvoid OLED_I2C_Init(void){GPIO_InitTypeDef GPIO_InitStructure;I2C_InitTypeDef I2C_InitStructure;RCC_APB1PeriphClockCmd(OLEDI2C_RCC, ENABLE);RCC_APB2PeriphClockCmd(OLED_RCC, ENABLE);// Enable the multiplexing functionRCC_APB2PeriphClockCmd(RCC_APB2Periph_AFIO, ENABLE);GPIO_PinRemapConfig(GPIO_Remap_I2C1, ENABLE);//PB8——SCL PB9——SDAGPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_OD;GPIO_InitStructure.GPIO_Pin = OLED_SCL_Pin | OLED_SDA_Pin;GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz;GPIO_Init(OLED_Port, &GPIO_InitStructure);I2C_DeInit(OLEDI2C);I2C_InitStructure.I2C_Ack = I2C_Ack_Enable;I2C_InitStructure.I2C_AcknowledgedAddress = I2C_AcknowledgedAddress_7bit;I2C_InitStructure.I2C_ClockSpeed = 400000;I2C_InitStructure.I2C_DutyCycle = I2C_DutyCycle_2;I2C_InitStructure.I2C_Mode = I2C_Mode_I2C;I2C_InitStructure.I2C_OwnAddress1 = 0x10; // Fill in this address casually, do not do slave machineI2C_Init(OLEDI2C, &I2C_InitStructure);I2C_Cmd(OLEDI2C, ENABLE);OLED_Init(); //oled initializationOLED_Draw_Line("oled init success!" , 1, true, true);}

OLED_Draw_String

xxxxxxxxxxvoid OLED_Draw_String(char *data, uint8_t x, uint8_t y, bool clear, bool refresh){if (clear)OLED_Clear();SSD1306_GotoXY(x, y);SSD1306_Puts(data, &Font_7x10, SSD1306_COLOR_WHITE);if (refresh)OLED_Refresh();}

OLED_Draw_Line

xxxxxxxxxxvoid OLED_Draw_Line(char *data, uint8_t line, bool clear, bool refresh){if (line > 0 && line <= 3){OLED_Draw_String(data, 0, 10 * (line - 1), clear, refresh);}}

Experimental phenomenon

The OLed.hex file generated by the project compilation is located in the OBJ folder of the OLED project. Find the OLed.hex file corresponding to the project and download the program into the development board using FlyMcu software.

After the program is downloaded successfully: OLED will display oled init success! And OLED Class! The CONTENT.